- Imprimer

- Partager

- Partager sur Facebook

- Partager sur X

- Partager sur LinkedIn

Soutenance

Le 24 mars 2021

Grenoble - Presqu'île

Experimental testing and numerical modelling of the tensile and compression damage in Ultra-High Performance Concrete under impact loading

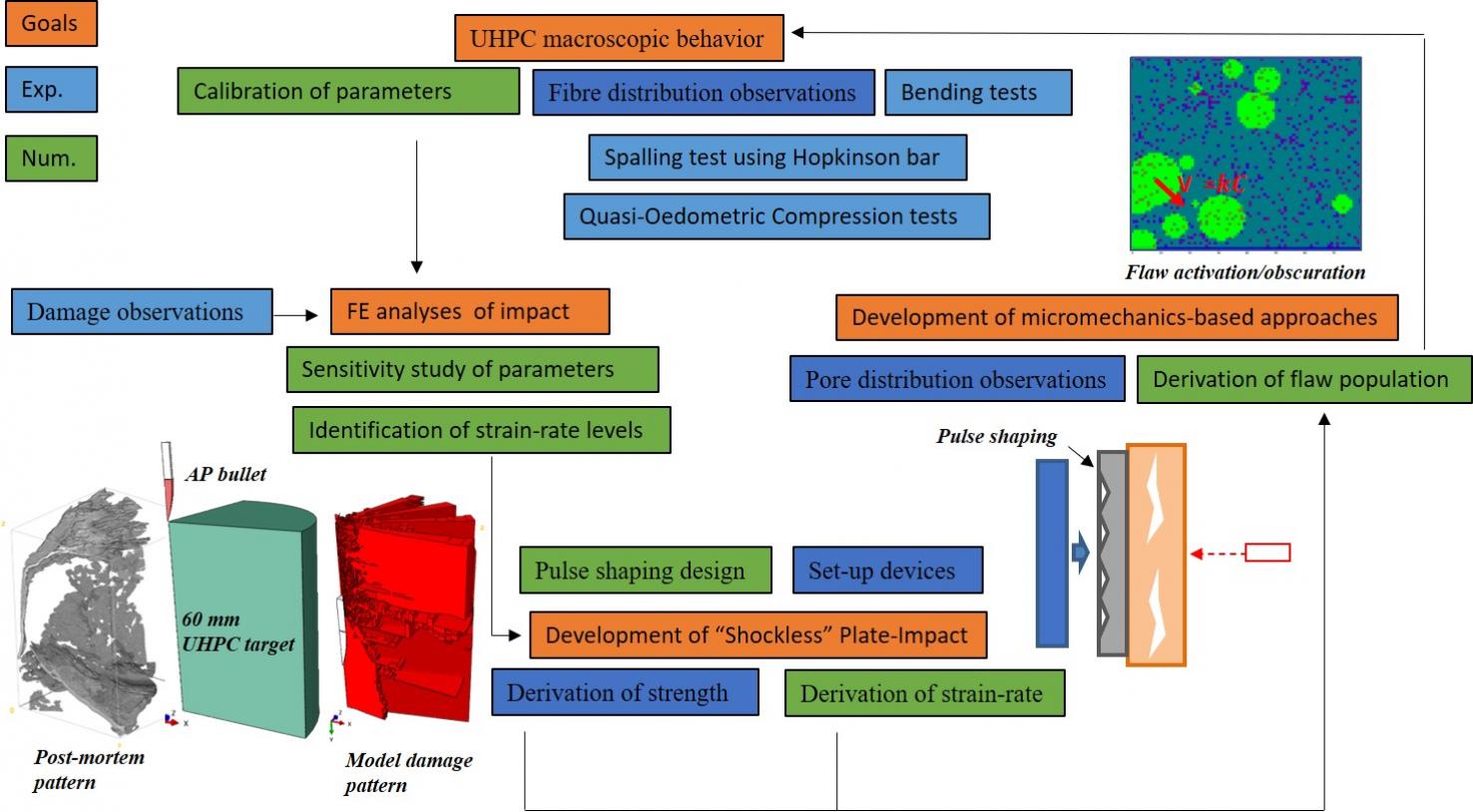

This thesis presents experimental and numerical investigations on Ultra-High Performance Concretes (UHPC) in view of intensifying their use in application demanding resistance to impact loadings. Under impact, concrete is exposed to high confinement stresses and high tensile loading rates, leading to severe damage modes affecting the ballistic performance. The DFHcoh-KST coupled model, describing the behavior under both confinement and dynamic tension, has been chosen to simulate with a Finite Element (FE) code the response of UHPC targets with fibre reinforcement under impact. In the model, the confining pressure is influencing the volumetric strain and the deviatoric strength. The strain rate effects are included in the description of the tensile damage based on the activation and obscuration of a Weibull distribution of flaws. The role of the fibres is integrated introducing a cohesion strength term.

The material parameters were identified for two Ductal® formulations using existing experimental techniques (Quasi-Oedometric Compression (Q-OC) tests, bending tests, and spalling tests at the Hopkinson bar) covering confinement pressure up to 500 MPa and a range of strain rates from 10-5 to 102 s−1. The validity domain of the proposed model was extended at very-high strain rates (above 103 s−1) by performing additional plate-impact tests, investigating the tensile response. A new testing technique employing a pulse shaping system to ensure a constant loading rate in the specimen was designed using numerical simulation and experienced using the single-stage gas gun installed in the 3SR laboratory. The fragmentation under dynamic tension was simulated with discrete and continuous micro-mechanics approaches based on X-ray Computed Tomography (CT) observations of the UHPC microstructure expressed as distribution of porosity. Assuming that the size of a pore is related to its stress of activation and that pores are connected to wing-end cracks about the size of the largest aggregate in the concrete formulation led to a flaw population that correctly described the observed tensile strength in the range of 103 - 104 s-1.

Jury

The material parameters were identified for two Ductal® formulations using existing experimental techniques (Quasi-Oedometric Compression (Q-OC) tests, bending tests, and spalling tests at the Hopkinson bar) covering confinement pressure up to 500 MPa and a range of strain rates from 10-5 to 102 s−1. The validity domain of the proposed model was extended at very-high strain rates (above 103 s−1) by performing additional plate-impact tests, investigating the tensile response. A new testing technique employing a pulse shaping system to ensure a constant loading rate in the specimen was designed using numerical simulation and experienced using the single-stage gas gun installed in the 3SR laboratory. The fragmentation under dynamic tension was simulated with discrete and continuous micro-mechanics approaches based on X-ray Computed Tomography (CT) observations of the UHPC microstructure expressed as distribution of porosity. Assuming that the size of a pore is related to its stress of activation and that pores are connected to wing-end cracks about the size of the largest aggregate in the concrete formulation led to a flaw population that correctly described the observed tensile strength in the range of 103 - 104 s-1.

Jury

Mr. Pascal FORQUIN Professor, Université Grenoble Alpes, Directeur de thèse

Mr. Marco DIPRISCO Professor, Politecnico di Milano, Reviewer

Mr. Jaap WEERHEIJM Associate Professor, TU Delft, Reviewer

Mr. François TOUTLEMONDE Ingénieur Général des Ponts, Université Gustave Eiffel, Examiner

Ms. Magali ARLERY Ingénieur, CEA/DAM, Examiner

Mr. Jean-Luc HANUS Associate Professor, INSA Centre Val de Loire, Examiner

Mr. Emmanuel BONNET Ingénieur, R&D LafargeHolcim, Invited

Mr. Dominique SALETTI Associate Professor, Université Grenoble Alpes, Invited

Mr. Julien BAROTH Associate Professor, Université Grenoble Alpes, Invited

Mr. Marco DIPRISCO Professor, Politecnico di Milano, Reviewer

Mr. Jaap WEERHEIJM Associate Professor, TU Delft, Reviewer

Mr. François TOUTLEMONDE Ingénieur Général des Ponts, Université Gustave Eiffel, Examiner

Ms. Magali ARLERY Ingénieur, CEA/DAM, Examiner

Mr. Jean-Luc HANUS Associate Professor, INSA Centre Val de Loire, Examiner

Mr. Emmanuel BONNET Ingénieur, R&D LafargeHolcim, Invited

Mr. Dominique SALETTI Associate Professor, Université Grenoble Alpes, Invited

Mr. Julien BAROTH Associate Professor, Université Grenoble Alpes, Invited

Date

Le 24 mars 2021

Complément date

11H00

LIEN ZOOM

Localisation

Grenoble - Presqu'île

Complément lieu

amphi P05 bâtiment Polygone (GreEn ER) 21 Avenue des Martyrs 38000 Grenoble

- Imprimer

- Partager

- Partager sur Facebook

- Partager sur X

- Partager sur LinkedIn