- Share

- Share on Facebook

- Share on X

- Share on LinkedIn

Soutenance

On April 23, 2021

Experimental and numerical analysis of the failure modes induced in ceramic materials under dynamic loading

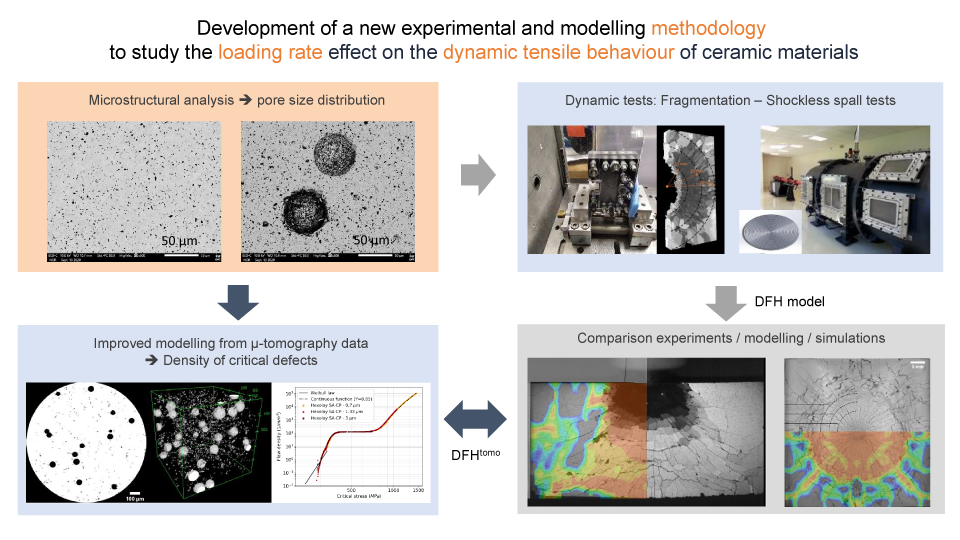

Due to their high resistance to extreme loading conditions, ceramic materials have been extensively investigated to be part of vehicle and body armour protections. Combined to a ductile backing, ceramics are very interesting for lightweight bulletproof systems. The link between damage mechanisms occurring in the ceramic upon impact and its microstructural properties is still not well understood. For this reason, a make-and-shot iterative approach is the common way followed to develop this type of material. However, such an optimisation process is very expensive, time consuming and hardly leads to any conclusions on the link between microstructural features and ballistic performance. The first goal of this PhD is to bring insight on the connection between microstructural properties of the ceramic armour and its failure mechanisms under dynamic loading. The natural second step consists in using these results to improve a modelling, which is representative of ceramic brittle damage under tensile loading on a large range of strain rates.

Ceramics are highly sensitive to the presence of inherent defects. Under low loading rate, they have a stochastic strength linked to the size of the most critical defect in the loaded volume. The common approach consists in using quasi-static tests to identify the defects responsible for failure (Weibull approach) and assumes that the same ones are causing failure at high loading rates. Such an assumption is questioned in the present work. Under high strain rate, numerous cracks are triggered simultaneously from multiple defects, causing an intense and deterministic fragmentation. Six ceramic materials, presenting different microstructural features, are analysed and tested under dynamic conditions in this project. Highly instrumented edge-on impact, normal impact and tandem impact dynamic tests, combined with a micro-tomography analysis of damage patterns, provided a better understanding of the fragmentation properties of the different grades of ceramics. A shockless experimental spalling technique was developed to evaluate the intrinsic tensile strength sensitivity to strain-rate of ceramic materials. To do so, the plate-impact configuration was adapted, using specific flyer-plate geometries designed to generate a tailored loading in the sample. From a hybrid approach mixing numerical simulations and experimental results, the spall-strength of the tested ceramic can be related to a well-controlled loading rate.

A new methodology is proposed to model the multiple fragmentation process induced in ceramics under high strain rate. This method is built on the identification of material defects (mainly pores) from micro-tomography analysis. This realistic description of the defect distribution is explicitly implemented in the Denoual-Forquin-Hild (DFH) damage model to predict the dynamic failure behaviour of ceramics under tensile loading, through so-called continuous and discrete approaches. A comparison with experimental results of fragmentation and spalling tests provided a validation of the approach. Predictions of this micro-mechanical model were compared for a Weibullian distribution of critical defects and a description based on micro-tomography analyses. Comparisons on a large range of strain rates showed that, for materials presenting multiple flaw populations, the Weibull-based solution is highly invalid. In this case, the use of a proper flaw description, obtained via micro-tomography, is much more relevant. These results highlight the importance of considering microstructural features to properly model the failure behaviour of ceramics at high loading rate, and therefore move toward a design of the next generation of ceramic-based armour protections.

Mr. Yannick CHAMPION Research director CNRS, Laboratoire SIMaP – Vice-President

Mr. Stéphane ROUX Research director CNRS, ENS Paris Saclay – Reviewer

Mr. Michel ARRIGONI University Professor, ENSTA Bretagne – Reviewer

Mr. Daniel EAKINS Associate Professor, University of Oxford – Examiner

Mr. Eric BUZAUD PhD Engineer, CEA Gramat – Examiner

Mr. Emmanuel BONNET Ingénieur, R&D LafargeHolcim, Invited

Mr. Pascal FORQUIN University Professor, Laboratoire 3SR – PhD Director, Examiner

Mr. Jérôme BRULIN PhD Engineer, Saint-Gobain Research Provence – Co-supervisor, Invited

Ms. Alexane MARGOSSIAN PhD Engineer, Saint-Gobain Research Provence – Co-supervisor, Invited

Mr. François BARTHELEMY PhD Engineer, DGA Techniques Terrestres – Co-supervisor, Invited

Date

10H00

Suivre en direct ici

Localisation

amphitheatre Kilian 1381 Rue de la Piscine, 38610 Gières

- Share

- Share on Facebook

- Share on X

- Share on LinkedIn